Precision Metal Fabrication: From Residential to Industrial Scale

Metal fabrication stands bernhardt custom fabrication near me as a fundamental pillar of modern construction, design, and industry, transforming raw materials into essential components and intricate structures. From the smallest decorative accents in a home to the colossal frameworks of industrial facilities, the principles of cutting, bending, and assembling metal are universally applied. This discipline marries artistic vision with engineering precision, creating durable and functional elements that shape our everyday environments.

The evolution of metal fabrication techniques has been remarkable, moving from rudimentary blacksmithing to highly sophisticated processes involving computer-aided design and automated machinery. Today, the demand for both aesthetic appeal and structural integrity drives innovation in the field, pushing fabricators to achieve ever-greater levels of accuracy and customization. Companies like Bernhardt Custom Fabrication LLC are at the forefront, leveraging decades of experience with cutting-edge technology to meet diverse project requirements.

Whether it’s enhancing the curb appeal of a residence or constructing robust infrastructure for a factory, metal fabrication caters to a vast spectrum of needs. Residential applications often focus on elegant gates, bespoke railings, or unique architectural features that add character and value. In contrast, industrial projects prioritize strength, safety, and operational efficiency, demanding components that can withstand extreme conditions and heavy usage.

Achieving superior results in metal fabrication requires a delicate balance of craftsmanship and advanced technical expertise. Skilled fabricators must possess a deep understanding of metallurgy, welding techniques, and structural mechanics, alongside an eye for detail. This blend ensures that every piece, regardless of its scale, not only meets precise specifications but also adheres to the highest standards of quality and longevity. When searching for "bernhardt custom fabrication near me," clients expect this level of dedication.

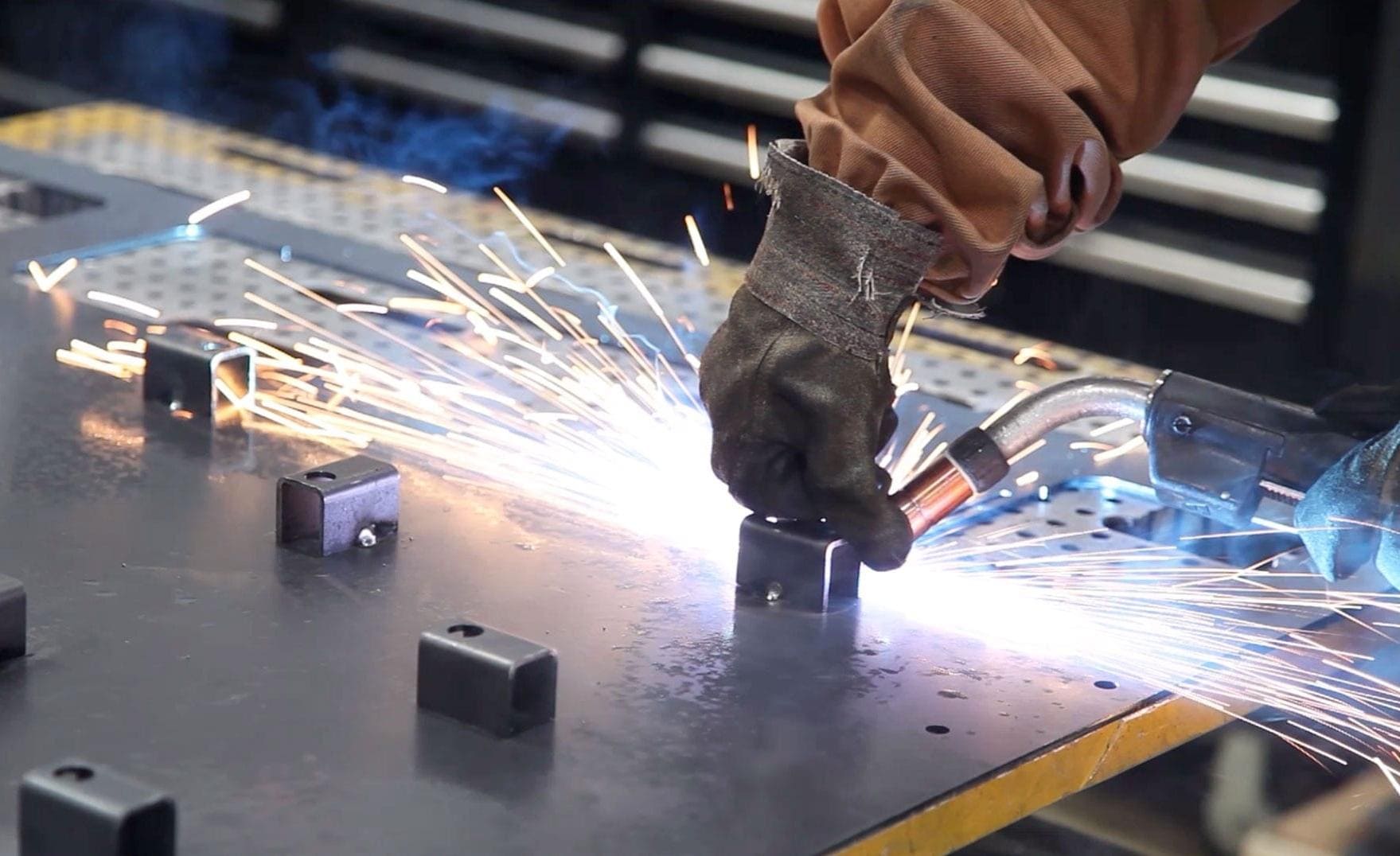

The critical role of specialized equipment cannot be overstated. From precision laser cutters and CNC plasma machines to powerful press brakes and advanced welding apparatus, the right tools enable fabricators to execute complex designs with unparalleled accuracy. This technological prowess, combined with seasoned experience, allows providers of custom metal fabrication services to tackle projects ranging from simple repairs to intricate, multi-stage builds.

Furthermore, the ability to provide comprehensive solutions, encompassing everything from initial design consultation to final installation, is what sets leading fabrication companies apart. Services such as local welding and fabrication are crucial for both new constructions and the maintenance of existing structures, ensuring that projects are completed efficiently and to exact specifications, regardless of their complexity or location.

Versatile Applications of Precision Fabrication

- Residential Enhancements: Custom gates, railings, and decorative metalwork elevate home aesthetics and security. Benefits include increased property value and personalized design; however, bespoke items often require a higher initial investment.

- Industrial and Commercial Structures: Structural steel components, machinery frames, and specialized equipment are vital for operational integrity. Advantages are superior strength and durability under demanding conditions, though projects demand strict adherence to safety and engineering standards.

- Specialized and Artistic Projects: Unique art installations, custom furniture, and prototypes demonstrate creative possibilities. These offer unparalleled individuality and innovation but typically involve intricate design challenges and specialized material handling.

Navigating the Complexities of Modern Fabrication

One of the enduring challenges in the fabrication industry is the delicate act of balancing cost-effectiveness with the imperative for high precision. Clients across all sectors, from those seeking intricate precision custom metal works to large-scale industrial clients, expect flawless execution within practical budgets. This often necessitates innovative approaches to material sourcing, process optimization, and project management to deliver exceptional value without compromising quality.

The debate between traditional craftsmanship and increasingly automated processes continues to shape the industry. While advanced robotics and CNC machinery offer unparalleled speed and accuracy for repetitive tasks, the nuanced skill of a master welder or the creative problem-solving of an experienced fabricator remains irreplaceable for unique designs and complex assemblies. A truly modern fabrication shop integrates both, leveraging technology where appropriate and relying on human expertise for critical, bespoke elements.

Material selection and robust engineering design are paramount to project success, particularly for a structural steel fabrication company. Understanding the properties of different metals—their tensile strength, corrosion resistance, and weldability—is crucial for ensuring the longevity and safety of the final product. Expert fabricators work closely with engineers to select the optimal materials and design solutions that meet performance requirements and regulatory standards.

The rising demand for bespoke solutions underscores the need for adaptability and innovation within the fabrication sector. Clients increasingly seek unique, tailored products that address specific functional or aesthetic requirements, moving beyond off-the-shelf components. Companies offering custom steel design and build services thrive by translating complex visions into tangible realities, requiring a collaborative approach from concept through to completion.

Technological advancements, such as sophisticated laser cutting, 3D modeling, and advanced welding techniques, have dramatically expanded the capabilities of metal fabricators. These tools not only enhance precision and reduce waste but also enable the creation of previously impossible geometries. This continuous integration of new technologies is vital for providing cutting-edge industrial welding services and efficient metal repair contractors, ensuring the industry remains responsive to evolving demands.

Looking Ahead: The Future of Fabrication

Metal fabrication is a dynamic and indispensable field, consistently adapting to new challenges and opportunities across residential, commercial, and industrial scales. Its fundamental role in building our physical world, from aesthetic enhancements to critical infrastructure, ensures its continued relevance and importance.

Choosing a fabricator with a proven track record, comprehensive capabilities, and a commitment to precision is paramount for any project. The blend of traditional skill and modern technology, coupled with a deep understanding of client needs, defines excellence in this specialized industry.

As materials science evolves and design possibilities expand, the future of precision metal fabrication promises even greater innovation. The ability to transform raw metal into functional and beautiful forms will continue to drive progress, creating durable solutions that stand the test of time and meet the ever-changing demands of a developing world.

Comments ( 0 )

Leave a comment